Tekinoloni wa diamondi yodula imadziwikanso kuti kuphatikiza ukadaulo wodula. Ndi kugwiritsa ntchito mawonekedwe a electropropting kapena respen njira ya diamondi yophatikizika pamwamba pa waya wachitsulo, diamondi ya waya zomwe zimachitika pamtunda wa rod kapena silika i indot kuti mupange kupera kukukuta, kuti mukwaniritse mphamvu yodula. Kudula kwa waya diamondi kumakhala ndi mawonekedwe odulira mwachangu, kudula kolondola komanso kutaya kochepa.

Pakadali pano, msika umodzi wa kristalo wa waya diamon Warmen Wafer adalandiridwa kwathunthu, koma adakumana nawo pakulimbikitsa, zomwe velvet Woyera ndi vuto lodziwika bwino kwambiri. Poganizira izi, pepala ili limayang'ana momwe tingapewere waya wa diamondi yodula monocrystalline walvet velvet yoyera.

Njira yoyeretsera ya waya diamondi yodulira monocrystalline silicon imachotsa chida cha waya kuchokera pa prin mbale, chotsani Mzere wa rabani, ndikuyeretsa sikitiyo. Zipangizo zotsuka ndizomwe zimatsuka (makina osungira) ndi makina oyera. Njira yayikulu yoyeretsera makina oyeretsa ndi: kudyetsa-spray-spray - madzi oyeretsa opanga akuluakulu. Njira yayikulu yoyeretsera makina oyeretsa ndi: Madzi odyetsa madzi oyera okhwima-alkali okhwima madzi okhwima-alkali okhwima madzi osambira-alkali-pre-pre-pre-pre-oyera (kukweza pang'onopang'ono) - kudyetsa.

Mfundo ya Kupanga kwa Crystal

Moncrystalline Silicon Wafer ndiye mawonekedwe a Anisotropic Colossion ya monocrystalline sililic yoyala. Mfundo yomwe ikuchitika ndi njira yotsatirayi yotsatira:

SI + 2nao + H2o = Na2sio3 + 2H2 ↑ ↑

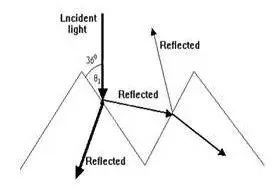

Chifukwa chake, njira yopanga ma suede ndi: Naohh njira yosiyanasiyana ya crystas yosiyanasiyana kuposa (111), kotero (100) kwa anocrystalline chithokomiro, pamapeto pake adapangidwa pamwamba . Kapangidwe kake kapangidwe, pomwe Kuwala kukuchitika pamalo otsetsereka ku Pyramid pa ngodya inayake, kuwunika kudzawonetsedwa kutsetsereka kwina, ndikupanga mayamwidwe kapena kuchepetsera njirayo pamtunda wa silwen , ndiye kuti, wopewa mwachangu (onani Chithunzi 2). Zabwino kwambiri ndi kufanana kwa "piramidi", zodziwikiratu, ndipo kutsikira kumatalika kwa silika.

Chithunzi 1: Micromorogy of Monocrystalline Silicon atapanga ma alkali

Chithunzi 2: Mfundo yowala ya "piramidi"

Kusanthula kwa zoyera zokha

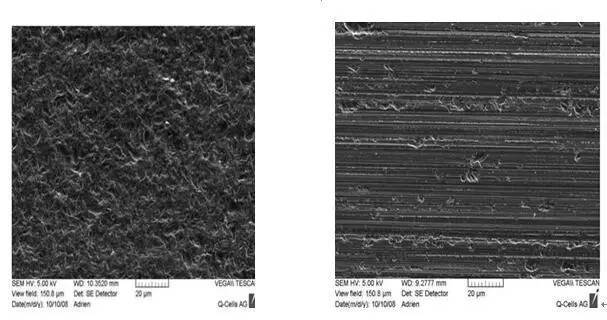

Mwa kusanthula ma microscope pa Silicon yoyera, idapezeka kuti micremid microstructuctuctuctuctuctuctuctuctustuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuctuste ya Pyramid mawonekedwe oyera M'dera loyera la silikicon yemweyo adapangidwa bwino (onani Chithunzi 3). Ngati pali zotsalira pamtunda wa Monocrystalline Silicon Warmer, malo omwe ali ndi malo otsalira "am'mibadwo osakwanira ndi osakwanira, zomwe zimapangitsa kuti malo abwinobwino akhalepo. malo okhala ndi malingaliro apamwamba poyerekeza ndi malo abwinobwino omwe akuwoneka kuti ndi oyera. Monga tikuwonera kuchokera ku zogawikana za malo oyera, sikuti mawonekedwe wamba kapena okhazikika m'dera lalikulu, koma kumadera akumaloko. Ziyenera kukhala kuti zodetsa zakomweko padziko lapansi pa silika.

Chithunzi 3: Kuyerekeza ndi micrestory microptuction Microstle yoyera mu velvet White Slika

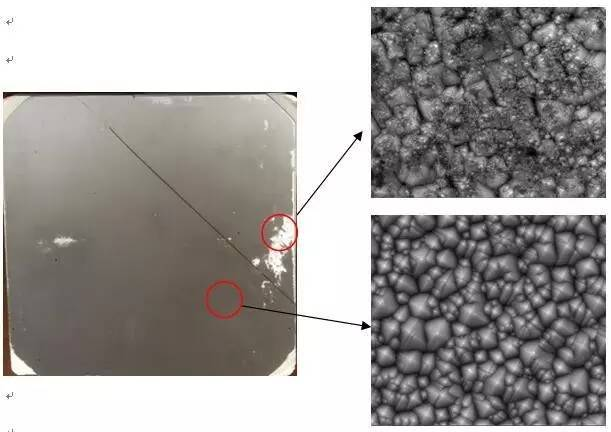

Pamwamba pa waya wa diamondi kudula silicnon imangokhala yosalala ndipo kuwonongeka kwake ndi kocheperako (monga tikuonera Chithunzi 4). Poyerekeza ndi silicon ya matope, liwiro la alkali ndi waya wa diamon Wargen porting monoctalline zotsatira za velvet zotsatira za velvet ndizodziwikiratu.

Chithunzi 4:

Gwero lalikulu lotsalira la waya wa diamondi-ridicon mwal

. Madzi odulira omwe ali ndi luso labwino amakhala ndi kuyimitsidwa bwino, kubalalika komanso kuthekera kotsukidwa. Zogwiritsa ntchito nthawi zambiri zimakhala ndi katundu wabwino kwambiri, zomwe ndizosavuta kuyeretsa mu njira yotsuka ya silicon. Kusunthika kosalekeza ndi kufalikira kwa zowonjezera m'madzi kumatulutsa thovu, zomwe zimapangitsa kuchepa kwa kuyenda kwa ozizira, kuchititsa chithovu chachikulu, ndipo chimavuta kwambiri kugwiritsa ntchito. Chifukwa chake, ozizira nthawi zambiri amagwiritsidwa ntchito ndi wothandizira. Pofuna kuonetsetsa kuti mukuwongolera, silika yachikhalidwe ndi polyther nthawi zambiri imakhala yosavuta hydrophilic. Zosungunulira m'madzi ndizosavuta kwa Adsorb ndikukhalabe pamwamba pa silicon yoyenga yoyambirira yotsatira, chifukwa cha zovuta za malo oyera. Ndipo sizigwirizana bwino ndi zigawo zikuluzikulu za ozizirawo, chifukwa chake, ziyenera kupangidwa m'magawo awiri, zigawo zikuluzikulu komanso zosokoneza, malinga ndi vuto la chitholo, sizitha kuwongolera Gwiritsani ntchito ndi mlingo wa othandizira antifoam, amatha kuloleza mankhwala osokoneza bongo, omwe amachititsa kuti kuchuluka kwa dipicon Zipangizo, chifukwa chake, ambiri mwa ozizira omwe amagwiritsa ntchito mankhwalawa; Wozizira wina amagwiritsa ntchito wothandizira watsopano, amatha kukhala ogwirizana ndi zigawo zikuluzikulu, palibe zowonjezera, zomwe zimatha kuwongolera kwambiri, zomwe zimatha kusintha kwambiri, ndikutsuka koyenera, zake. Zotsalira zitha kuwongoleredwa pamiyeso yotsika kwambiri, ku Japan ndi opanga ochepa nyumba amatengera dongosolo ili, komabe, chifukwa chamtengo wake wobiriwira, mtengo wake suwoneka.

. waya wayamba kudula ku rabay wosanjikiza, popeza gululo lokwera la silicon ndi malo ogulitsa a epoxy ndi pakati pa 55 ndi 95 ℃ Phala ndi lotsika, limatha kutentha mosavuta mukamacheza ndikusungunuka, ophatikizika ndi chingwe chodulira ndi Wokhazikika ndi utoto, akamamangirizidwa, ndizovuta kwambiri kutsuka, kuipitsidwa kotero kumachitika pafupi ndi m'mphepete mwa silikic konga.

(3) Silicon ufa: Mukudula kwa waya diamoni ufa wa ufa wambiri, ndikudula, pomwe ufa wozizira ndi wokulirapo, adzatsata mawonekedwe, Ndipo maya am'madzi a diamon ufa kukula ndi kukula kwake kumadzetsa zovuta kwa Adsorption pamiyeso ya silikicone, zimapangitsa kuti zikhale zovuta kuyeretsa. Chifukwa chake, onetsetsani kuti zosintha ndi mtundu wa ozizira ndikuchepetsa ufa mu kozizira.

. Mzere wathunthu wa mzere, wofunda ndi matope ali ndi kusiyana kwakukulu, kotero njira yoyeretsera, njira yoyeretsera, formula, etc iyenera kukhala yosinthira yolingana. Kuyeretsa ndi gawo lofunikira, ma alkaliani oyeretsa oyambira, Alkalianity sioyenera kuyeretsa waya wa diyirani, kuyenera kukhala pansi kwa waya wa diamon wolemera, ndikukhala ndi njira yoyeretsera. Monga tafotokozera pamwambapa, kapangidwe kake ka mankhwala osafunikira sikufunikira matope.

.

Kuchepetsa vuto lopanga tsitsi loyera loyera

.

.

.

.

. Nthawi yomweyo, imawonjezeranso kusintha kwa kutentha kwa madzi, kuyenda ndi nthawi pakutsuka koyamba, kuonetsetsa kuti ufa wa sulicon umatsukidwa mu nthawi

.

. .

.

. Mfundo yake ndiyofanana ndi njira yoyeretsera sc1 (yodziwika bwino ngati madzi 1) ya semiconducy silicon yokwera. Njira yake yayikulu: filimu ya oxidation pa lilemen pamwamba imapangidwa ndi oxidation ya H2o2, yomwe imabisidwa ndi Naoh, ndi kutupa ndi kututa ndikupezeka mobwerezabwereza. Chifukwa chake, tinthu tating'onoting'ono tomwe timaphatikizidwa ndi ufa wa silika, utoto, chitsulo, ndi zina) amagweranso mu madzi oyeretsa ndi osanjikiza; Chifukwa cha makutidwe ndi okosijeni a H2o2, organic nkhaniyo pamalo a Wafal amawola mu CO2, H2O ndikuchotsedwa. Njira yoyeretsa yakhala opanga silika pogwiritsa ntchito njirayi kuti ikonzere maya a socrystan opanga madandaulo a Monocrystan Order. Palinso opanga a batire omwe agwiritsa ntchito njira yofananira yofananira, ndikuwongolera bwino maonekedwe a velvet yoyera. Zitha kuwona kuti njira yoyeretsa iyi imawonjezeredwa mu njira yotsuka ya silika yoyeretsa kuti ichotse malo otsalira a silicon kuti muthetse bwino tsitsi loyera kumapeto kwa batri.

mapeto

Pakadali pano, kudula kwa waya wa diamondi kwasanduka ukadaulo waukulu wosinthira kumbuyo kwa kudula kwamtundu umodzi, koma pakupanga vuto lopanga velvet Wricon War Wamer ali ndi kukana. Kudzera mu kuwunika koyerekeza kwa malo oyera, kumachitika makamaka chifukwa cha nthawi yotsala ya sil. Kuti zinthu zithetse vuto la silicon limasanthula magwero omwe angawonongedwe, komanso kusintha malingaliro ndi njira zosinthira ndi njira zopangira. Malinga ndi kuchuluka, dera ndi mawonekedwe a mawanga oyera, zomwe zimayambitsa zimatha kusanthulidwa ndikusintha. Zimalimbikitsa kwambiri kugwiritsa ntchito hydrogen peroxide + alkali. Zomwe zidamuyendera bwino zatsimikizira kuti zimalepheretsa bwino vuto la waya wa diamoni lomwe limatulutsa velvet yoyera, chifukwa chofotokoza za General Imlers ndi Opanga.

Post Nthawi: Meyi-30-2024